This was a fun collaboration with my dear madre! She does bookmaking along with letterpress and about 100 other hobbies. See where I get it from? When making a hardcover book you have a solid material that is covered with something like fabric or heavy paper. I forget all the terms, but in order for it to get covered nicely you need to cut the corner off the cover material so it folds in well. It is kind of like wrapping a present.

I was directed to check out the cool 3D printed corner tool here: https://www.ibookbinding.com/tools/3d-printed-corner-cutting-tool/

It was a good looking tool, but the tall wall used to protect fingers made it a lot harder to use. In woodworking we use guides like this all the time to cut knife lines in wood. You want it to be low so you can get a flat single beveled knife up against the guide. I made a few changes and came up with this.

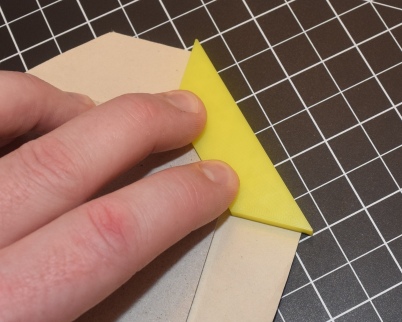

It sits on the corner of binding material up to 1/8″ thick, and provides a 45 degree standoff of 1/8″ from the very tip of the corner. I added that funny circle cutout to make sure the printer didn’t round the corner to the inside any. This sits snugly.

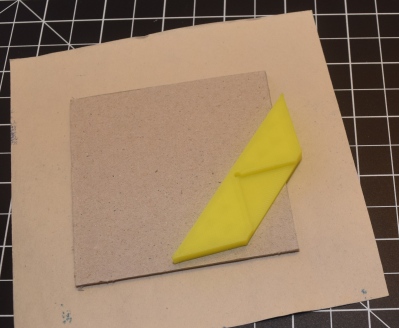

Here is an example of a binder board and the cover material. The tool sits on the corner of the hard binder material.

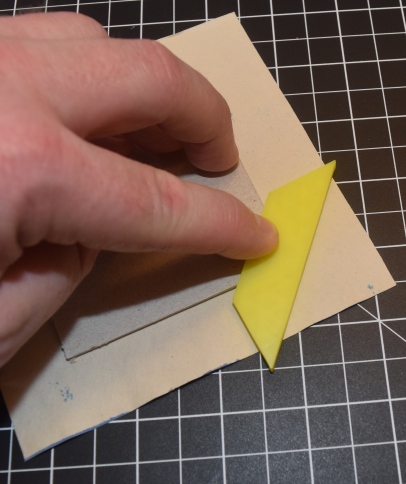

With fingers sufficiently out of the way, you can run a knife along the outside edge and trim the corner off.

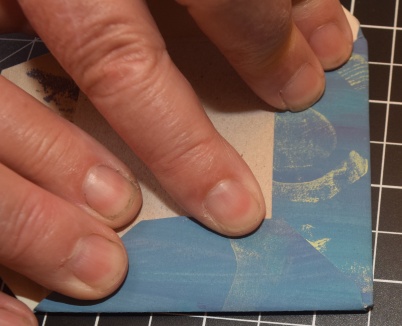

With all corners trimmed you can do a little fold and crease and get a smart looking book cover.

Mom was happy and requested a dozen. Easy enough! Thingiverse link for those that want their own copy

roll a lot smoother. Any catches or resistance in the spool rolling could cause Z banding as the extruder fights to pull in filament. Thingiverse had a great assembly that sits on top. It included a printable threaded nut and bolt that turned out gorgeous! Skate bearings pressed into the rollers so the spool rolls with little resistance. A filament guide keeps it running true.

roll a lot smoother. Any catches or resistance in the spool rolling could cause Z banding as the extruder fights to pull in filament. Thingiverse had a great assembly that sits on top. It included a printable threaded nut and bolt that turned out gorgeous! Skate bearings pressed into the rollers so the spool rolls with little resistance. A filament guide keeps it running true.